Community

osapeers.org

This article is available in

About this article

Jessica Hollfelder

AuthorAssigned categories

With the European Union Deforestation Regulation (EUDR), the EU is taking decisive action against global deforestation. Starting December 30, 2025, certain commodities and their derivatives – including cocoa, coffee, soy, palm oil, cattle, timber, and rubber – may only be placed on the EU market if they can be proven not to contribute to deforestation, such as through forest clearing.

The requirements are strict: companies must ensure that their products are fully traceable – all the way back to the plot of land. This includes providing precise geolocation data, conducting a risk analysis regarding origin and deforestation exposure, and submitting a Due Diligence Statement (DDS) before import or sale. Violations can result in steep fines, import bans, and reputational damage.

Wholesalers and manufacturers are among those most affected. Both must analyze and document – often complex – supply chains and prove compliance with the EUDR in a legally sound manner. Those who invest in automated EUDR compliance software now are laying the foundation for smooth, timely, and reliable implementation.

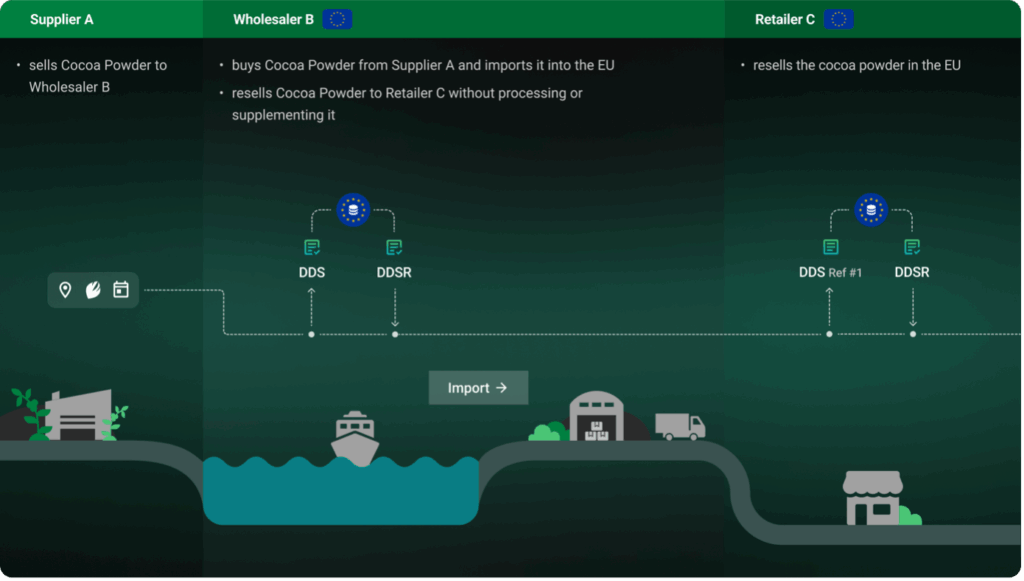

Wholesalers play a pivotal role under the EUDR. As the first point of entry for deforestation-relevant commodities such as cocoa, coffee, or timber into the EU, the legal duty of care starts with them. The regulation sets out clear expectations around transparency, traceability, and risk assessment.

Example: A wholesaler imports cocoa powder from Ghana and sells it to retailers in Germany. Even though the product remains unchanged, the wholesaler is responsible for ensuring that the cocoa is deforestation-free and must submit the corresponding DDS. Retailers may use this DDS, but they are required to verify that the information is valid and complete.

One key element in the risk assessment process is the origin of the imported product. The EU Benchmarking System classifies countries into different risk categories, helping businesses evaluate deforestation exposure more effectively. To understand how this affects your supply chain and how to handle mixed batches, check out our blog post: “What the EUDR Benchmarking Means for Your Supply Chain – and How to Respond”.

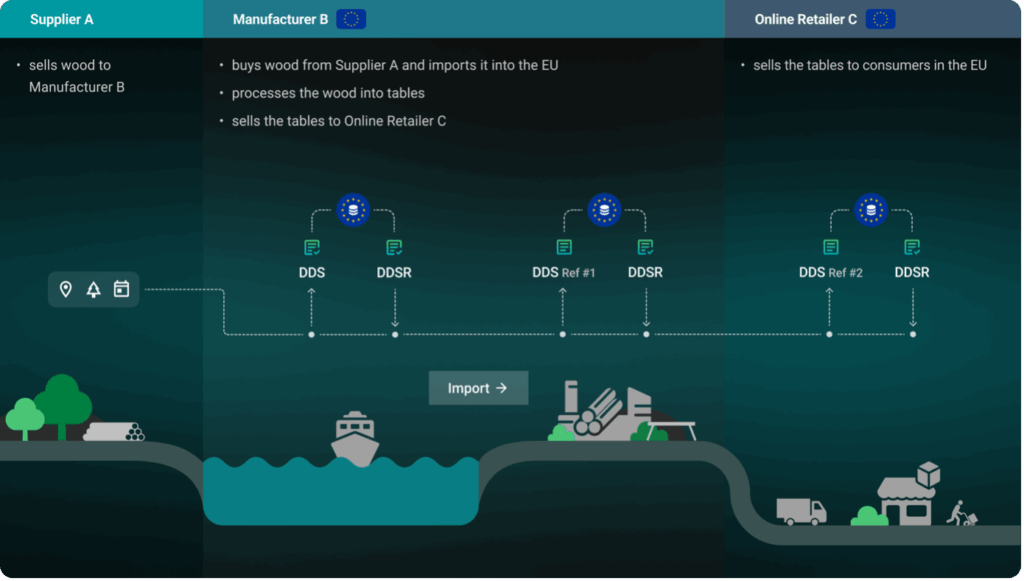

The situation becomes more complex for manufacturers – especially those who import raw materials, process them, and then sell the finished goods. The EUDR applies to each stage of this journey, with specific rules manufacturers must follow:

Example: A manufacturer imports timber from Indonesia and uses it to produce garden furniture. Before import, a DDS for the raw material must be submitted. Once the wood is processed, the company must submit a new DDS for the final product, which references the initial DDS. If the product is sold to an online retailer, that retailer may also need to submit a DDS – again referencing the earlier submissions.

Wholesalers and manufacturers are both part of the same supply chain – and both must meet the EUDR’s core requirements: deforestation-free sourcing, full traceability, and accurate data. However, their roles differ significantly in complexity and responsibility. While wholesalers typically operate in linear supply chains and pass on unchanged goods, manufacturers deal with layered networks of raw materials, processing steps, and finished products.

Key differences at a glance:

| Aspect | Wholesalers | Manufacturers |

| Processing | No processing – products are resold in their original form | Raw materials are processed (e.g., wood → furniture, cocoa → chocolate) |

| DDS required | One DDS before importing into the EU | Two DDS: one before import and one before placing the final product on the market |

| Complexity | Focus on verifying origin, conducting risk assessments, and submitting the DDS | Additional DDS required for each product combination or processing activity |

| Traceability | Based on origin – applies to raw materials only | Based on both origin and production – including internal aggregation and assignment |

| Responsibility | Remains with the wholesaler, even if the retailer uses the DDS | Remains with the manufacturer, even when other actors are involved downstream |

Whether you’re a wholesaler or a manufacturer, the osapiens HUB for EUDR automates the entire due diligence process and adapts to your specific role within the supply chain.

The result: Less manual effort, full transparency, audit readiness at any time – and compliance as a competitive advantage.

Companies that invest in transparency today secure their ability to act in a shifting regulatory environment – and actively contribute to a sustainable, deforestation-free supply chain.