Community

osapeers.org

This article is available in

About this article

Jessica Hollfelder

AuthorAssigned categories

As the EU Deforestation Regulation (EUDR) moves closer to full implementation, businesses across the globe are preparing to meet its stringent due diligence requirements. A key component of this regulation is the country benchmarking system. This mechanism is designed to help companies assess the deforestation risk associated with sourcing key commodities from different countries.

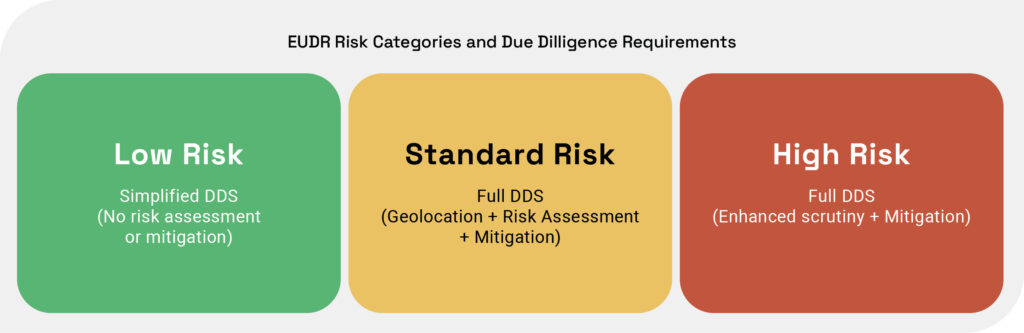

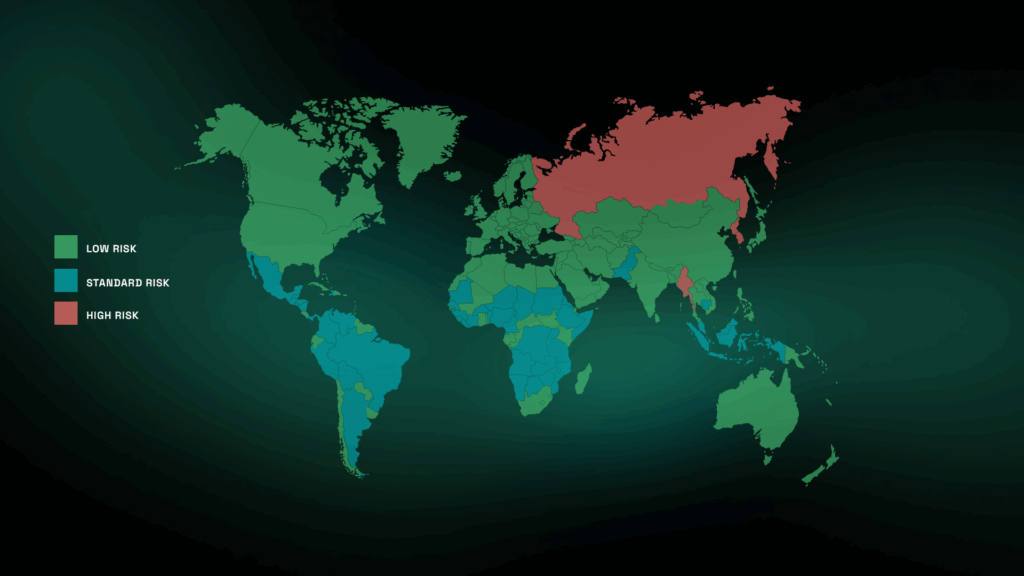

By classifying countries into low, standard, or high risk, the EU aims to create a more targeted and efficient compliance process. But while the system offers clarity at a high level, it also introduces new complexities – especially for companies with global, multi-tiered supply chains. Understanding how the EU benchmarking system works, and how it affects your sourcing and risk management strategies, is essential for staying compliant and competitive in a rapidly evolving regulatory landscape.

The EUDR’s country benchmarking system is a classification tool developed by the European Commission to assess the deforestation risk associated with the production of key commodities in different countries. It applies to seven regulated commodities: cattle, cocoa, coffee, oil palm, rubber, soya, and wood – as well as certain products derived from them.

The benchmarking list is not static. It will be reviewed and updated regularly, meaning that companies must stay informed and be ready to adapt their sourcing strategies as classifications change. This dynamic nature is intended to incentivize producer countries to improve forest protection and governance to move toward a lower risk category.

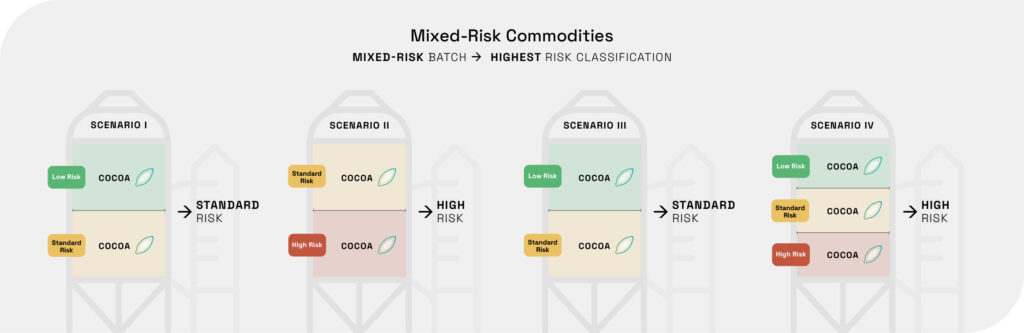

One of the most operationally relevant rules of the EUDR benchmarking system is how it handles mixed-risk commodities. According to the regulation, if products from different risk categories are stored, transported, or processed together – such as in shared silos, warehouses, or containers – the entire batch is classified according to the highest risk level present.

This means that if even a small portion of the mixture originates from a high-risk country, the entire volume must be treated as high risk. The same applies if standard-risk material is mixed with low-risk goods. The full batch is then considered standard risk.

This rule is designed to prevent circumvention of the regulation through blending or aggregation. However, it also presents a significant challenge for companies that rely on bulk logistics or shared infrastructure, especially in sectors like cocoa, coffee, soy, or palm oil.

For example:

As a result, companies must rethink how they manage storage, transport, and traceability. Segregation strategies and digital tools that can track origin at batch level become essential for maintaining compliance and minimizing risk exposure.

While the benchmarking system provides a useful starting point, relying solely on country-level classifications can be misleading. Deforestation risk is not uniform across an entire country. It can vary significantly between regions, production areas, and even individual suppliers. That’s why it’s increasingly important to conduct risk assessments at the supplier level.

This more granular approach allows companies to:

Supplier-level risk assessment also helps companies to future-proof their supply chains. As the EU continues to refine and expand its sustainability regulations, more detailed traceability and risk data may become mandatory. Companies that already have supplier-level insights will be better positioned to adapt quickly and maintain market access.

In short, going beyond the benchmarking list isn’t just about compliance – it’s about building a smarter, more resilient supply chain that can withstand regulatory, reputational, and environmental risks.

Real-world supply chains are rarely linear. Products are often stored in shared silos, transported in bulk, or manufactured using components from multiple suppliers, each potentially linked to a different risk category. These complexities make manual due diligence not only time-consuming, but also error-prone and difficult to scale.

That’s where the osapiens HUB for EUDR comes in. The AI-powered solution automates the creation of Due Diligence Statements (DDS) by integrating benchmarking data, supplier-level risk profiles, and mitigation measures into a single, reliable process.

Here’s how it works:

This level of automation not only ensures regulatory compliance, but also increases transparency, reduces administrative burden, and provides a clear audit trail for authorities and business partners alike.

The EU’s benchmarking system is only one piece of the EUDR puzzle. Many companies still rely on static country lists – but that won’t be enough. EUDR compliance requires full traceability, geolocation data, ongoing risk assessments, and auditable due diligence. Companies that wait risk falling behind – or losing market access altogether.

Smart compliance isn’t just a checkbox – it’s your competitive edge. With osapiens HUB, you put EUDR compliance on autopilot – reducing complexity, eliminating guesswork, and ensuring legal certainty. Act now and secure your supply chain.