Community

osapeers.org

This article is available in

About this article

Di Liao

AuthorAssigned categories

Industrial maintenance is entering a decisive phase of transformation. Across Europe’s factories and production sites, maintenance teams are under pressure to achieve more with less – higher uptime, lower costs, and demonstrable ROI – while dealing with increasingly interconnected equipment, fragmented data sources, and growing regulatory and sustainability demands. At the same time, aging infrastructure and a shrinking skilled workforce are making it harder to maintain consistent performance with traditional methods.

For decades, maintenance was viewed as a cost center focused on fixing breakdowns and keeping machines running. Today, it’s evolving into a strategic lever for performance, resilience, and sustainability. Modern maintenance directly impacts performance by improving equipment reliability and optimizing production throughput. It strengthens resilience by minimizing dependency on individual expertise and enabling faster recovery from disruptions. And it supports sustainability through longer asset lifecycles, lower energy consumption, and reduced waste from unplanned repairs.

This shift is driven by the rise of connected assets, the availability of real-time operational data, and the accelerating adoption of AI and advanced analytics that turn this data into actionable insights for continuous improvement.

The study Industrial Maintenance in Transition gathered insights from more than 400 maintenance decision-makers across key European regions – including the UK, DACH, Benelux, and France. The findings reveal a shared challenge across all markets: while confidence in digital maintenance is high, the level of execution remains unbalanced and varies significantly between regions. Some organizations are already advancing toward connected, predictive operations, while others are still dependent on manual routines and fragmented systems.

Key findings:

This gap between conviction and capability makes one thing clear: digital transformation in maintenance is no longer a question of awareness – it’s a matter of integration and consistency. Many teams still rely on disconnected systems, spreadsheets, or local expertise to manage critical assets. This fragmented approach results in uneven progress across regions, limited transparency over asset performance, and slower reactions to downtime or production disruptions, all of which prevent organizations from realizing the full efficiency and ROI potential of digital maintenance.

Maintenance departments are shifting from reactive “firefighting” toward preventive and, ultimately, predictive operations. Yet reaching predictive capability requires more than installing sensors or software. It demands a cultural and organizational shift, one that integrates maintenance data with production planning, workforce management, and corporate strategy.

AI is emerging as the catalyst for this change. When combined with structured data from a connected CMMS, it transforms day-to-day operations into an integrated ecosystem. Capabilities such as digital work orders and smart forms, asset management, and automated planning and scheduling bring transparency and speed to every stage of the maintenance process, from identifying faults to allocating resources.

Paired with spare parts and inventory control and structured preventive maintenance, these capabilities enable early fault detection, precise task execution, and data-driven decisions that minimize downtime and extend asset life. What was once limited to high-budget pilot projects is now within reach for mid-sized manufacturers, providing measurable ROI and a scalable foundation for predictive maintenance.

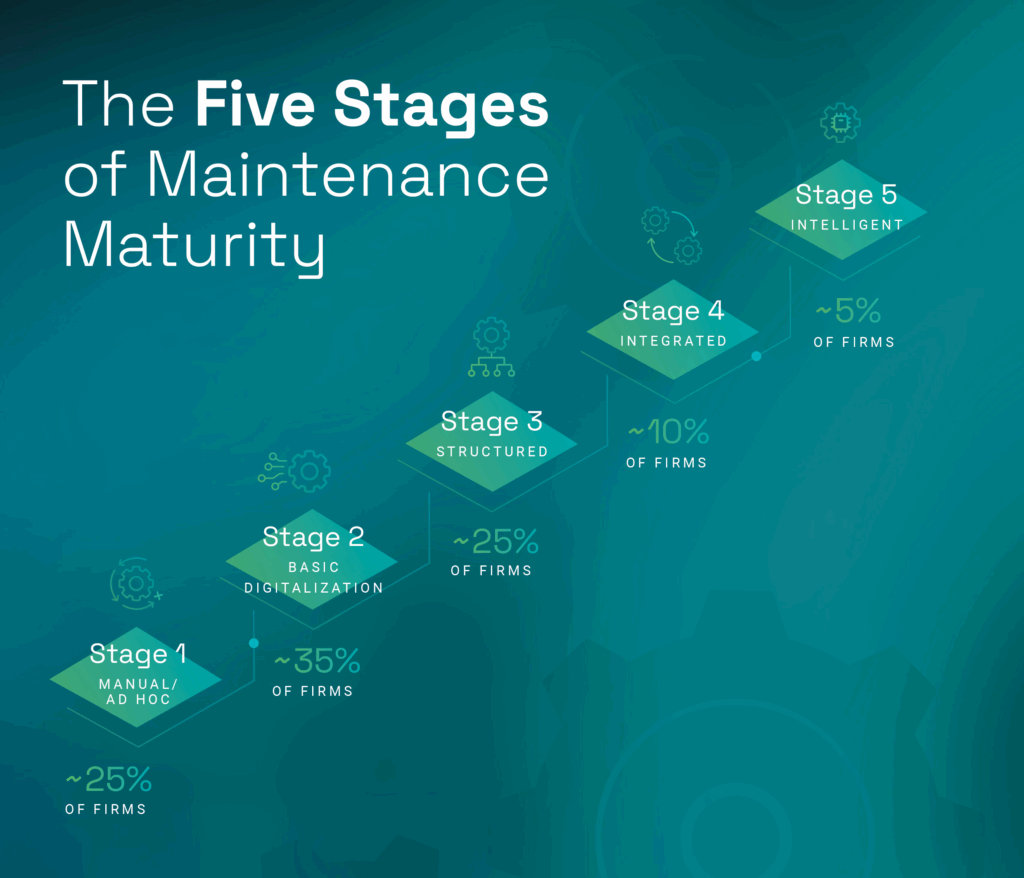

To help organizations navigate this complex journey, osapiens and Fraunhofer IML co-developed the Maintenance Maturity Index: a five-stage framework that defines the progression from manual, ad-hoc processes to fully predictive, AI-enabled maintenance.

The Index serves as both a diagnostic and a roadmap. It allows maintenance leaders to benchmark their current practices, identify the next logical stage of improvement, and align investment decisions with operational priorities.

What makes the framework especially relevant is its realism: most companies sit somewhere between the “basic digitalization” and “structured” stages. Progressing further often hinges not on technology alone but on the integration of data flows, workforce enablement, and management buy-in.

Explore the full framework in the report and see where your organization stands on the Maintenance Maturity Index.

The shift toward predictive maintenance is no longer just an operational upgrade; it’s a measurable driver of financial performance. Organizations using connected CMMS platforms report fewer unplanned downtimes, faster work order completion, and higher technician efficiency. These improvements translate directly into reduced maintenance costs, increased equipment availability, and stronger overall productivity.

With tools such as the Maintenance ROI Calculator, teams can estimate their own potential savings in time, cost, and efficiency, turning digital progress into clear business value. The data is conclusive: digital maintenance is not an experiment in innovation; it is an economic necessity for sustainable industrial performance.

Maintenance is moving from reactive repair to predictive intelligence, a transformation reshaping how industrial organizations plan, operate, and compete. The next challenge is not proving the value of digital maintenance but scaling it consistently across sites, systems, and teams.