Community

osapeers.org

This article is available in

About this article

Hardik Agrawal

AuthorAssigned categories

In December 2025, the EU approved a targeted revision of the EUDR to give companies and supporting systems more time to prepare. Ahead of further guidance, the Commission has invited stakeholder input. Contributions are due by the end of January 2026, with early submissions encouraged to feed into ongoing work. A formal next milestone follows on April 30, 2026, when the Commission must publish a “simplification review”, and report on the EUDR’s impact and administrative burden.

Under the amended regulation, the core application date moves from December 30, 2025, to December 30, 2026, for medium and large operators and traders. For Micro and small companies, the EUDR will apply from June 30, 2027.

The main point is simple: the EUDR application date has changed, not the core obligations. The EUDR framework, product scope, and due diligence structure remain part of EU law.

This one-year delay allows better preparation and targeted administrative relief, without weakening the regulation’s environmental goals. A major driver is operational readiness, including the stability and scalability of the EUDR Information System EU TRACES. Hence, this extra time is meant to reduce implementation risk and help companies build more reliable, automated processes.

What doesn’t change is the core obligation set, especially for first operators (importers). Since fully implemented EUDR processes take months to design and embed, the smart move now is to use the runway to map products and suppliers, put the right systems in place, and build audit-ready workflows.

Under the amended EUDR (Regulation 2025/2650), impact depends on one clear factor: your role in the supply chain. The regulation particularly distinguishes between first operators and downstream operators or traders.

First operators are companies that place an in-scope product on the EU market for the first time*. In practice, this typically includes importers, EU manufacturers placing relevant products on the market, and EU exporters.

For first operators, the one-year postponement provides additional time to implement scalable, audit-proof processes. Their compliance obligations, however, stay the same. First operators must still conduct end-to-end due diligence, which includes:

For non-EU companies, the key question is who imports the goods into the EU.

Check out our EUDR for Importers Checklist to further understand the importer’s role, scope, and key definitions.

Downstream companies handle products after they have already been placed on the EU market. This includes traders (like wholesalers, distributors, and retailers) and downstream operators that process already-placed goods into new relevant products.

EUDR-related administrative burden has been reduced for downstream operators, as they no longer need to submit an independent DDS. However, downstream companies still need to keep products linkable to an upstream DDS, retain the relevant information for at least 5 years, and be able to respond to checks by competent authorities. In practice, this means:

Find out exactly where you stand within the EUDR, and what you need to do next, in under a minute. Take the questionnaire.

The extra year creates room to strengthen processes and reduce implementation risk. Companies that use this time to standardize data, automate workflows, and improve traceability will enter late 2026 with far less operational pressure.

For first operators, the priority is industrial-grade due diligence. Requirements stay the same, so the focus should shift to execution at scale: automated processes, scalable system setups, and audit-ready data structures. Use 2026 to move DDS creation and validation into repeatable workflows, tighten supplier data collection (especially geolocation), and build documentation trails that hold up in inspections.

For downstream operators and traders, the priority is traceability and control. Preparation still matters even with simplified TRACES-related steps, because reference numbers and product flows must remain linkable to upstream due diligence. Without full supply chain transparency, risk management breaks down and legal exposure increases. Use the extra time to improve data capture, reference number handling, recordkeeping, and readiness to respond quickly to authority requests.

Whether you are just starting, mid-implementation, already EUDR-ready, or not yet in scope, there are clear, practical actions that reduce risk and prevent last-minute pressure. The following recommendations outline what to focus on now, based on your current EUDR maturity.

Start with scope and mapping. Identify all EUDR-relevant products, commodities, and CN/HS codes. Map suppliers and sourcing regions tied to them. This creates clarity on exposure and effort.

Next, define requirements and target setup. Determine which data is needed (geolocation, plots, chain of custody, certifications), who owns it internally, and how automated the process must be by 2026/27. Manual setups won’t scale to shipment-level DDS and ongoing monitoring, which is why early tool selection is critical.

Teams that maintain momentum during this stage avoid bottlenecks and supplier pressure in the long run. Use the extra time to deepen supplier engagement, improve data quality, and test workflows. Early transparency exposes gaps while there is still time to fix them. This reduces compliance risk and operational stress as deadlines approach.

Treat EUDR as infrastructure, not a one-off project. Mature setups can be reused for supplier management, risk monitoring, and reporting, because the same data models underpin supply chain transparency and other due-diligence regimes.

This is also the moment to reassess automation depth. If processes still rely heavily on manual work, ROI is capped. Best practice focuses on reducing effort through reuse of data, smarter workflows, and increased automation across compliance, procurement, and sustainability teams.

Even companies that are out of scope for now benefit from baseline supply chain transparency. Regulation scope may expand over time, enforcement priorities can shift, and customers increasingly demand verifiable, deforestation-free sourcing.

For such companies, a transparency or due-diligence self-assessment is often the most efficient first step to understanding current readiness and identifying gaps.

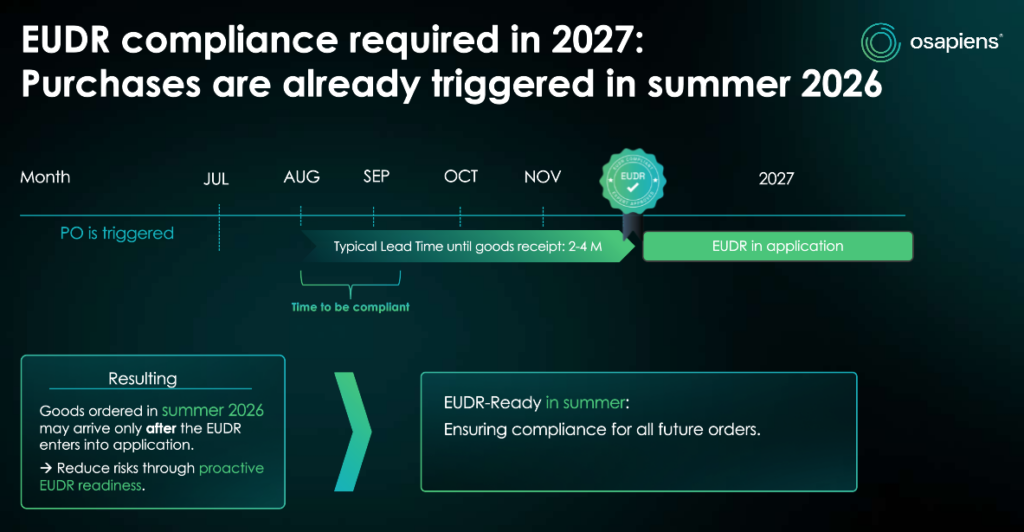

A purchase order is placed months before goods arrive, and compliant documentation has to exist before shipment and customs processes start pulling it. That’s why EUDR readiness needs to be planned backwards from your real supply-chain cycle: order → lead time → inbound goods, with supplier data and due-diligence evidence running ahead of the flow.

Many companies need several months to implement scalable, automated EUDR processes and drive the internal change across procurement, compliance, logistics, and IT. Starting late compresses supplier onboarding, data collection, and process redesign into an unrealistic window and increases the risk of gaps on early shipments.

If you are still feeling unsure about how to get started, we conduct live EUDR Readiness webinar series, that offers a steady, low-pressure way to stay oriented as the landscape changes. Register for the next session!

The EUDR timeline has shifted, but the operational reality stays the same. Teams need to be ready well before the formal start date to avoid late-stage bottlenecks. A realistic project plan runs through scoping, supplier data collection, system integration and testing, then a ramp-up into daily operations.

This end-to-end flow typically takes several months to set up. Companies that use the additional year to secure compliance, build supply chain transparency, and automate their processes will be ready when enforcement starts, and better positioned than competitors who wait.

EUDR should not be treated as a one-off compliance obligation, but a starting point for broader transparency, risk management, and regulatory readiness. With the osapiens HUB for EUDR, companies can replace manual workarounds with a scalable setup that combines traceability, risk assessment, and automation in one platform. The result: faster compliance, lower operational effort, and a more resilient approach to managing supplier data in an increasingly regulated market.

Book an EUDR readiness assessment with osapiens to map your fastest path to operational compliance and stronger supplier transparency.