Community

osapeers.org

This article is available in

About this article

Jessica Hollfelder

AuthorAssigned categories

One of the biggest changes in the Packaging and Packaging Waste Regulation (PPWR) is not a rule about materials or recyclability. It is the way the regulation assigns responsibility. The PPWR makes it clear that:

For many businesses, this is the hardest part of PPWR. It requires companies to assess every packaged item and define their role with precision. Getting this wrong can lead to missing obligations, incomplete documentation, or delays in placing products on the EU market.

PPWR uses four main roles to describe who is responsible for what, when packaging is placed on the EU market. These roles are simple in theory but complex in practice: a single company can hold different roles depending on the product.

Under the PPWR, a producer is any manufacturer, importer, or distributor established in the EU who makes packaging or packaged products available for the first time in a specific EU Member State. Producers fall under the Extended Producer Responsibility (EPR) framework.

Producers must register with the relevant national authorities and are responsible for financing the collection, sorting, and recovery of packaging waste through EPR fees in each Member State where they place packaging on the market.

Example: An online shop imports packaged consumer goods from outside the EU and sells them to customers in Germany and Austria. For PPWR purposes, the online shop acts as a producer in both countries and must register (or appoint a legal representative) and pay EPR fees in each market.

A manufacturer is the company that physically produces the packaging. They create the packaging material or component, even if someone else sells it.

Example: A packaging company produces cardboard boxes for several brands. It does not sell the products inside the boxes, but as the producer of the packaging itself, it is the manufacturer.

An importer brings packaged goods from outside the EU into an EU Member State. The importer becomes responsible for ensuring that the packaging meets PPWR rules before it enters the EU market.

Example: A European electronics retailer buys headphones from a supplier in China. When the goods arrive in the EU, the retailer becomes the importer and is responsible for ensuring the packaging meets PPWR rules.

A distributor offers packaged goods within the EU but does not produce or import the packaging. They must make sure the packaging they sell is compliant and properly labeled.

Example: A wholesaler buys packaged food products from a producer in France and sells them to stores in Germany. The wholesaler is a distributor, because it moves the product within the EU but does not brand, design, or import the packaging.

A supplier provides packaging or packaging materials to a manufacturer. Suppliers do not place packaging on the market themselves, but they play a critical role in compliance through information provision.

Suppliers are required to provide the manufacturer with all relevant data needed to carry out the conformity assessment and to create the technical documentation, including material composition and compliance-related information.

Example: A foil manufacturer supplies plastic film that a food producer uses to wrap its products. The final packaging is labeled with the food producer’s name, but the foil manufacturer acts as a supplier under the PPWR and must provide the necessary compliance data.

These roles may overlap. A retailer with private-label products may be a producer for some items, a distributor for others, and an importer for all goods sourced outside the EU. This is why the PPWR pushes companies to classify each product individually.

Misclassification leads to misaligned compliance efforts. The PPWR assigns different duties to each role, such as:

Incorrect classification creates gaps that regulators can easily detect. It also complicates cooperation within the supply chain because responsibilities are unclear.

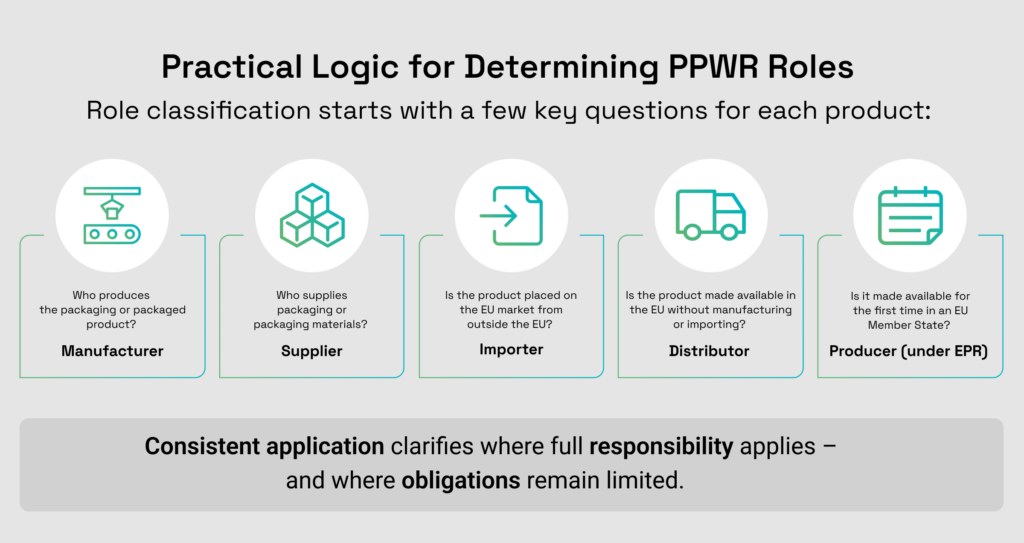

The most effective way to classify roles under the PPWR is to ask clear questions for each product:

Applying this logic consistently helps companies understand where they carry full responsibility and where their role is more limited. Many businesses will find that their responsibilities vary across product lines, regions, and sourcing models.

A supermarket chain sells its own-label pasta.

This means the retailer carries most of the compliance duties. If the same supermarket sells branded pasta from another label, it is usually a distributor – unless it imports the goods from outside the EU or repacks them, in which case it becomes the importer (and/or producer of the packaging).

An online marketplace ships products stored in its warehouse.

A company buys packaged electronics from a supplier in Asia.

These examples show why each product must be assessed individually – wrong assumptions lead to compliance errors under the PPWR.

The PPWR makes it challenging to keep track of roles and responsibilities, especially when products come from many sources. The osapiens HUB for Product Compliance simplifies this process significantly. It guides teams through each step, puts all role information in one place, and shows exactly what is required for every product. With clear workflows and connected data, companies can handle complex PPWR tasks with confidence and stay compliant across the entire supply chain.

Want to dive deeper into the topic? Download the osapiens PPWR Guide now.

New osapiens Study: Majority of European Companies Continue Sustainability Reporting After the Omnibus

Insights from Real Mid-Sized Company Projects: How VSME Reporting Simplifies Customer Requests and Enables Growth

osapiens and JELD-WEN Europe Partner to Deliver Next-Generation Supply Chain Transparency Ahead of EUDR Implementation