Community

osapeers.org

This article is available in

About this article

Di Liao

AuthorAssigned categories

Global supply chains are facing their most turbulent decade in memory. Geopolitical conflicts, environmental crises, and cyber incidents are rewriting the rules of global trade – yet the greatest risks often lie beyond the immediate line of sight.

Even organizations with advanced procurement systems and well-defined compliance programs struggle to gain complete visibility across multi-tier supplier networks. While Tier 1 relationships are typically well monitored, indirect suppliers remain difficult to map and assess. It’s in these deeper layers where hidden vulnerabilities can emerge: a raw material shortage, a local compliance breach, or a disruption at a sub-supplier that quietly cascades upstream.

At the same time, risk management processes remain fragmented and reactive. Data is distributed across multiple systems, assessments are handled manually, and information flows are rarely synchronized across departments. When a potential issue arises, teams often spend valuable time consolidating data rather than resolving the risk itself.

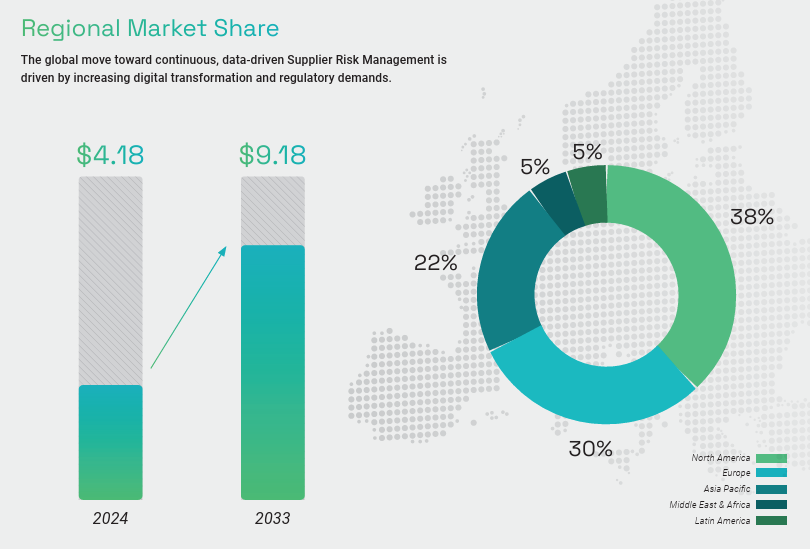

This widening gap between supply chain complexity and risk control is exactly why supplier risk management has moved to the top of executive agendas. The global supplier risk management market, valued at USD 4.1 billion in 2024 and projected to reach USD 9.1 billion by 2033 (CAGR 9.6%), reflects a shared recognition that resilience depends on achieving continuous, multi-tier visibility.

Despite significant progress in digitization, supplier risk management often remains dispersed across multiple tools and processes. Procurement, compliance, and sustainability teams each manage parts of the picture, such as supplier performance, audits, sanctions, ESG metrics, but rarely within one shared environment. This fragmentation is not the result of oversight; it’s a natural consequence of complex global operations and evolving regulatory demands.

However, the outcome is still the same: information scattered across systems makes it difficult to build a consistent, real-time view of supplier exposure. Manual onboarding and repeated assessments slow down collaboration. Inconsistent data creates uncertainty and makes it harder to spot emerging issues. And when risks surface, response depends on cross-team coordination that is too often slowed by disconnected workflows. Without a unified foundation, risk management remains reactive. Teams spend more time validating information than mitigating threats, while disruptions or compliance gaps continue to unfold unnoticed in the background.

The answer is not simply more data, but connected intelligence: the ability to detect, assess, and act on risks continuously and collaboratively. That shift, from static compliance checks to dynamic, end-to-end visibility, marks the turning point for modern supplier risk management.

Supply chains today demand more than static reports – they require real-time insights, continuous monitoring, and contextual understanding of risk. This means moving from periodic checks to ongoing surveillance across thousands of data sources, not only regulatory lists and ESG scores, but also open-source signals such as media coverage, litigation databases, and geopolitical developments.

This intelligence layer allows organizations to identify vulnerabilities early, model their potential impact, and take proactive action before disruptions escalate. It also transforms risk management from a compliance requirement into a strategic capability: the companies that see sooner and act faster secure supply continuity while competitors scramble to react.

Building such an intelligence framework requires several foundations:

Together, these elements create the shift from static compliance checks to dynamic, end-to-end visibility – the foundation for intelligent, proactive supplier risk management.

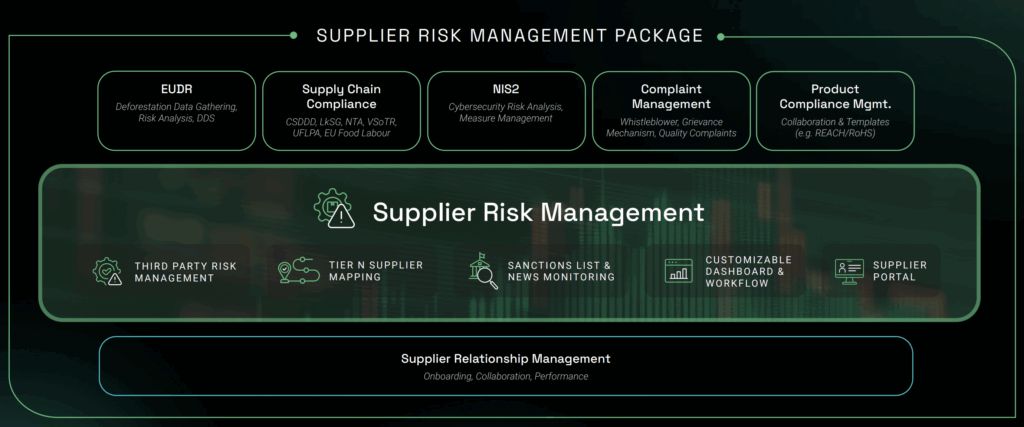

The principles of continuous intelligence come together in the osapiens HUB for Supplier Risk Management – a mature, field-tested solution that brings all these capabilities together on one connected platform. The platform continuously monitors thousands of data sources and scans suppliers across multiple tiers, giving companies a complete and up-to-date picture of their global supplier landscape.

With predefined supply chain risk dimensions and built-in regulatory risk frameworks (including CSDDD, CBAM, NIS 2, and EUDR), it provides a robust foundation – yet remains fully customizable to each organization’s specific policies, scoring models, and governance requirements. This flexibility allows companies to configure, extend, and adapt the solution to their unique risk landscape while maintaining regulatory assurance at scale.

Through the Supplier Portal, suppliers conduct self-assessments, available in multiple languages, eliminating duplicate requests and improving data quality across the network. Information collected once can be reused where applicable, ensuring suppliers spend less time on administration, and buyers gain faster access to verified, audit-ready data.

AI-powered enrichment and automated case management connect every risk signal, whether from sanctions lists, questionnaires, or global news monitoring, directly to the relevant supplier profile. This ensures transparency, traceability, and complete audit readiness at every step. Rather than introducing yet another tool, the osapiens HUB extends an existing ecosystem trusted by thousands of businesses worldwide. Its maturity, scalability, and depth of integration make it a proven foundation for organizations seeking to strengthen resilience, compliance, and trust across their supply chains.

Effective supplier risk management relies on integration. The osapiens HUB connects directly with ERP and procurement systems so that supplier data, assessments, and risk insights stay consistent across functions. Real-time synchronization replaces fragmented views with a single, current picture of exposure.

Role-based dashboards provide the right context for each stakeholder, from operational teams to executives. The platform’s no-code workflow builder allows users to easily configure or modify processes themselves – without IT support or lengthy implementation cycles. This makes it possible to adapt rapidly to new regulations, internal policies, or organizational structures while maintaining full governance.

Integration, in this sense, is not just technical – it creates shared understanding and faster, better-informed decisions across the organization.

Modern supply chains demand more than compliance; they demand credibility. With continuous monitoring and unified data structures, the osapiens HUB enables organizations to base decisions on verified, traceable information. Each risk signal can be linked to its origin, turning assessments into evidence rather than opinion.

This transparency builds confidence – internally among teams who rely on the data, and externally with suppliers and regulators who expect consistency. The result is a culture of assurance where compliance is a given, and attention shifts toward improvement and collaboration.

Resilience today depends on how well organizations connect their information, people, and processes. The osapiens HUB brings these elements together so that risk intelligence flows freely across departments and borders.

By combining AI-driven monitoring with structured workflows, it supports faster recognition of emerging issues and coordinated responses. The outcome is not a promise of zero disruption but a practical ability to adapt – seeing change early, acting decisively, and sustaining continuity even in uncertain conditions.

Supplier risk management is becoming a defining capability for resilient and responsible business. Explore how the osapiens HUB for Supplier Risk Management helps organizations achieve full supply chain visibility, meet regulatory expectations, and build lasting trust with suppliers.

Learn more and download the full guide