Community

osapeers.org

This article is available in

Assigned categories

Multi-ingredient products are complex, as the effort for traceability and transparency increases with every single ingredient. Each of the raw materials, which are often processed in global supply chains, is subject to different statutory requirements, not to mention the specific characteristics of their respective product categories. osapiens HUB for Food Traceability offers effective traceability solutions for multi-ingredient products.

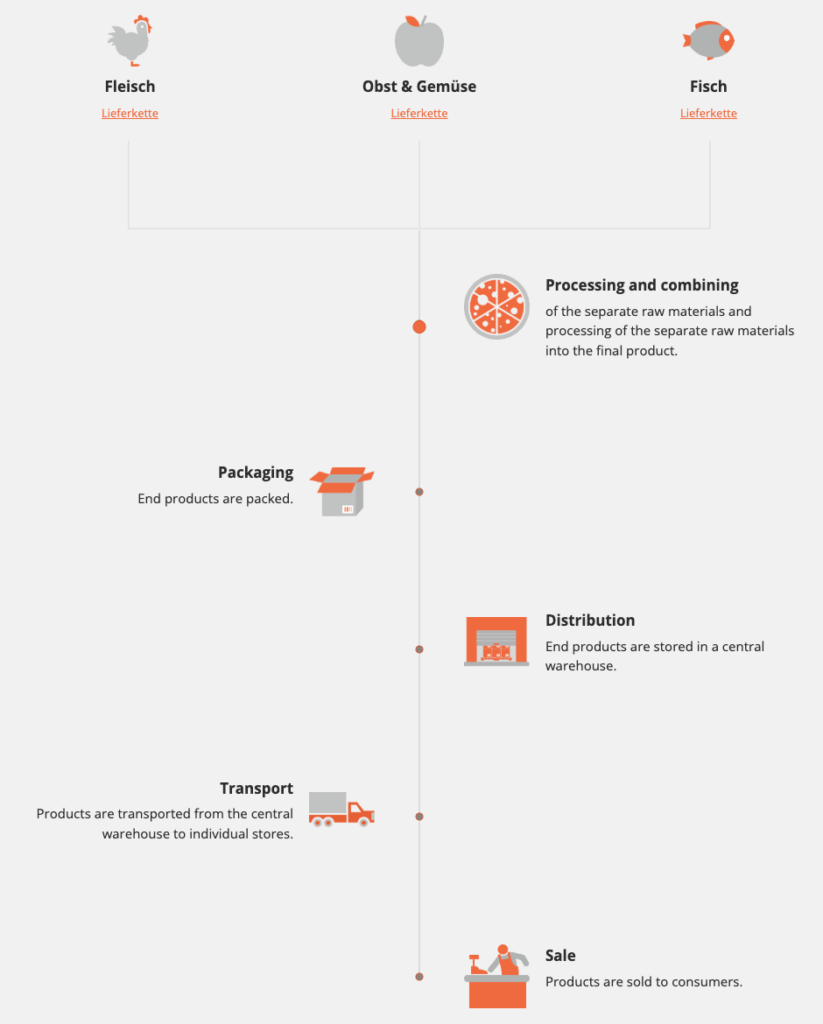

The raw materials contained in the end product originate from different slaughter processes, harvests or catches. They are then further processed into intermediary or end products.

For multi-ingredient products, it is essential to collect information about the origin and processing of the many different ingredients – for example, different cereals that have been processed in various ways, sugar, honey or the diverse range of ingredients in a pizza. osapiens HUB for Food Traceability allows all relevant cross-company information to be retrieved at the touch of a button and assessed in real time. Different areas of the business benefit from this – quality management and purchasing, for example, as well as corporate communications, PR and marketing. You always retain data sovereignty of your supply chains.

In the case of multi-ingredient products, a myriad of different supply flows need to be considered. Depending on the ingredients, a wide range of different information is pooled. This includes data relating to origin, processing, quality and sustainability, as well as nutritional information. The depth of data can be defined in the osapiens HUB according to individual needs – depending on what you as a company want to share with the consumer. By scanning the QR code on the product packaging, the information can be displayed in the necessary depth, or broken down for every ingredient.

osapiens HUB enables traceability from raw material to the consumer’s plate. This means that companies can implement a batch-specific risk management system along the entire supply chain. For example, if impurities are found in a batch of raw materials, the companies concerned can be quickly identified and the affected items removed immediately from the shelves. At the same time, the companies concerned have the capacity to provide statements at the drop of a hat – even when the flow of goods is part of a complex supply network. In a potential crisis situation, this capacity not only offers cost savings but also prevents damage to the company’s image.

A diverse range of different companies along the supply chain transfer data to the osapiens HUB for Food Traceability solution. The data is entered in accordance with specific criteria using standard interfaces. A sophisticated user rights management system prevents unauthorised parties accessing certain data. The rights to the data recorded in osapiens HUB always remain with the original owner. Only the owner has the authority to determine who is able to view the supply chain data they have entered and who is not.